Materials Our Printers Can Code On

From plastic water jugs to glass soda bottles and the cardboard boxes they ship in, Sneed Coding Solutions is always striving to provide quick turnkey solutions to your date and lot coding requirements. Allow our coders to increase productivity, reduce downtime, and precisely mark codes on several of your materials. Those materials include:

- Cartons

- Cans

- Plastic

- Glass

- Aluminum

- Cardboard

- Paper

- And more...

Having a dependable inkjet coder is crucial in the beverage industry, particularly when inkjet codes are used for tracking and traceability, as this is becoming more and more important. Manufacturers need to be able to rely on the accuracy of their marking system and to be confident their code is applied in the appropriate location on the appropriate product. Sneed Coding Solutions is well known for providing the top-performing coding and marking solution products on the market. We deliver consistent quality so that our clients can rest assured on the effectiveness of their coding and marking systems.

What Features Our Printers Offer

There are several benefits our products offer that are advantageous for bottle coding which include:

- No Maintenance

- No Service Contracts

- Easy Setup & Self-Installation

- Low VOC Inks

- UV/invisible inks

- Fast Dry Inks for Hard, Non-Porous Surfaces

- Automatic Rollover Dates

- Built-in Counters

- Barcodes, QR Codes and DM Codes

- And much more

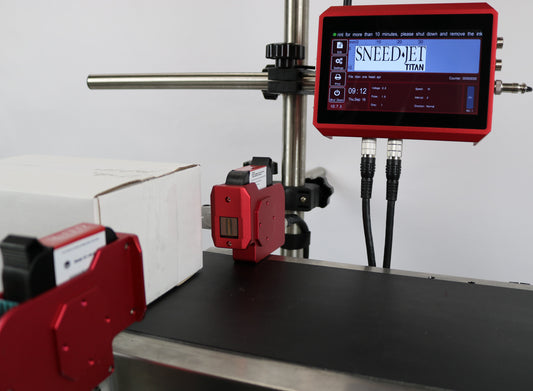

Inkjet Printers for Beverage & Bottle Coding

Regardless of what you need, Sneed Coding Solutions has you covered. For more information about how our inkjet printers can help with your bottle coding, schedule a time with one of our inkjet coding experts today here:

At Sneed Coding Solutions, we make it our top priority to offer the best possible products to #KeepCodingSimple.

These are the inkjet coders that make this possible: