Dependable Coding Systems

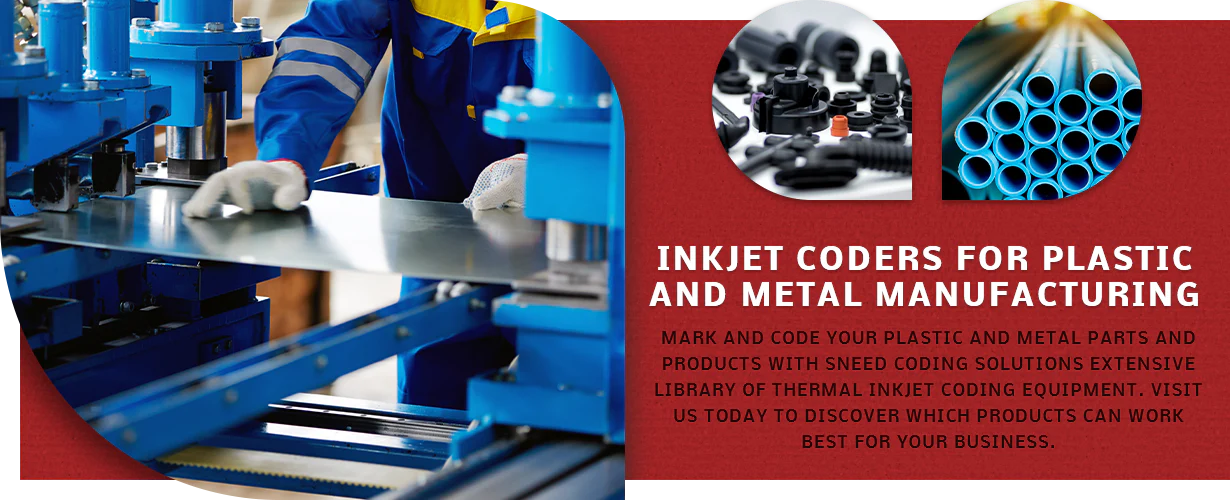

When it comes to our dependable inkjet coders for plastic and metal manufacturing, there is certain criteria that needs to be met.

The printing needs to be crystal clear, and the codes need to be readable to meet industry standards and regulations. Our inkjet coders will allow you to mark the appropriate code directly onto the product on the first round.

There are a variety of codes that help with tracking and traceability, product identification, and adhering to government regulations. Your system will be able to print all marking and codes with efficiency. Some of this information may include:

- Lot and batch codes

- Product information

- Date and time stamps

- Manufacturer’s name

- Heat numbers

- Material size and type

- Manufacturing standards

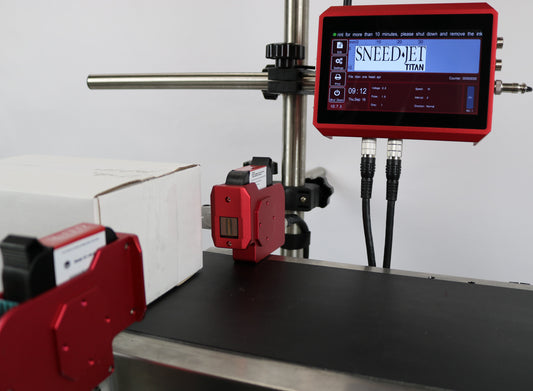

Plastic and metal production extrusion lines are running day in and day out. These companies need a system they can depend on that will accurately and efficiently mark their products while they are constantly moving. Downtime due to faulty printing isn’t something any company can afford to handle. All of Sneed Coding Solutions equipment requires minimal upkeep, maximizing efficiency.

What Features Our Printers Offer

There are several benefits our products offer that are advantageous in the food packaging industry which include:

- No Maintenance

- Fast Dry Inks for Hard, Non-Porous Surfaces

- No Service Contracts

- Automatic Rollover Dates

- Easy Setup & Self-Installation

- Built-in Counters

- Low VOC Inks

- Barcodes, QR Codes and DM Codes

- UV/invisible inks

- And much more…

Inkjet Coders for Plastic & Metal Manufacturing

Regardless of what you need, Sneed Coding Solutions has you covered. For more information about how our inkjet printers can help in the food product industry, schedule a time with one of our inkjet coding experts today here:

At Sneed Coding Solutions, we make it our top priority to offer the best possible products to #KeepCodingSimple.

These are the inkjet coders that make this possible: